GP Resin

Product Details:

- Type GP Resin

- CAS No 9002-86-2

- EINECS No 208-750-2

- Grade Industrial Grade

- Purity(%) High

- Application Industrial

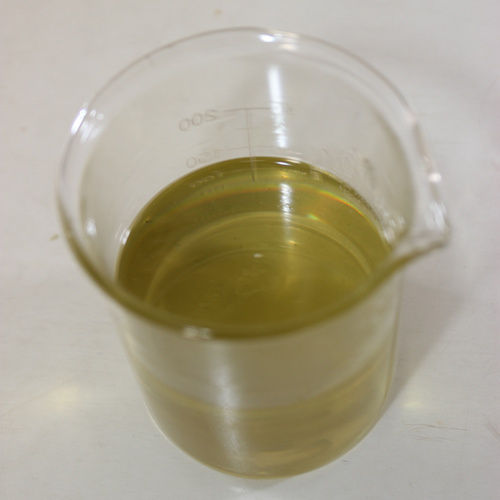

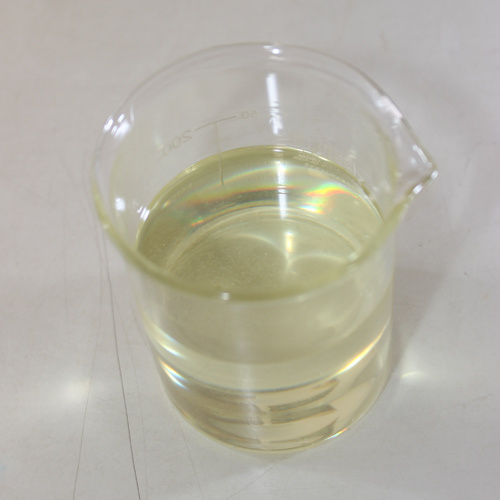

- Color Light Yellow

- Click to View more

GP Resin Price And Quantity

- 114 INR/Kilograms

- 35 Kilograms

GP Resin Product Specifications

- Industrial Grade

- High

- 9002-86-2

- GP Resin

- 208-750-2

- Industrial

- Light Yellow

GP Resin Trade Information

- AHMEDABAD

- Cash in Advance (CID) Cash Advance (CA)

- 5000 Kilograms Per Day

- 2 Days

- Yes

- Free samples are available

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

Description : BITCT-5402 is a medium reactive PET based resin suitable for hand layup and general application. It also has high filler capacity and has a low peak exotherm.

Application: BITCT-5402 is suitable for car patch putty formulations and other applications requiring high filler load and any other hand layup and general applications.

Physical data in the liquid state (conforms to IS 6746 -1994)

|

Property |

Unit |

Limits |

Test method |

|

Appearance |

|

Pale Yellow clear/hazy liquid |

|

|

Specific Gravity |

|

1.10 -/+ 0.01 |

|

|

Viscosity at 25 deg C - Brookfield LVT (2/30) |

Mpa.s (cPs) |

300-/+50 |

|

|

Acid Value |

Mg KOH/g |

1.10-/+0.01 |

|

|

Non-Volatiles Content |

deg C |

62-/+2 |

|

|

Gel Time 30 deg C |

deg C |

15-/+5 |

|

|

Peak Exotherm |

% |

190-/+10 |

|

|

Time To Peak Temp. |

Minutes |

10-/+2 |

|

|

Barcol Hardness |

B |

35 (Minimum) |

|

|

HDT |

deg C |

70 (Minimum) |

|

|

Stability in the dark at 25 deg C |

Months |

3 |

|

Using 1.5%Co (3%), 1.5% MEKP (50%)

Post curing Mature the laminate for 24 hours at room temperature, followed by post curing at 60 degC for 16 hours or at 80 deg C for 3 hours

Usage BITCT-5402 performs best if the laminate is completely post cured.

Since viscosity increases on the storage due to styrene evaporation, styrene may be added to lower viscosity.

Storage BITCT-5402 remains stable for 2 months at 30 deg C in the dark. The stability deteriorates markedly at elevated temperatures, especially when exposed to direct sunlight

Packing BITCT-5402 is packed in HDPE carboys (35 kg).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free